PRODUCTIVE

The Kirovets K-7M embodies all of the best technical principles required for a high-power tractor; equal-sized wheels, a massive articulated frame, ballasted for ideal weight distribution and auto-locking axles.

The Kirovets design is the key to the machines unsurpassed tractive performance; up to 10% better than conventionally-designed tractors of equivalent engine power.

ECONOMICAL

Kirovets tractors cost less to buy and less to run. With a listed price well below that of any equivalent tractor, a new Kirovets leaves more cash in a farmer’s pocket. They cost less to operate too; all models have fuel-efficient engines and drivetrains, low cost spares and simple, straightforward maintenance requirements, free from the overly complex and service intensive features common to many contemporary designs.

TOUGH

Since the first of the K-7 series was launched in 1962, more Kirovets machines have been produced than any other articulated tractor.

Designed to work under the world’s most difficult conditions, Kirovets tractors have solid construction, durable engines and a precision engineered drivetrain.

Designed to handle the big loads, a Kirovets is built to last.

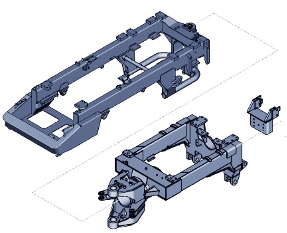

FRAME

The frame provides the structural platform of the tractor; a mounting for all of its power generating, transmitting and controlling parts. With ballast and a full fuel load, a Kirovets can weigh almost twenty tonnes. The frame needs to be strong enough to support the mechanical parts and absorb all the working loads, whether imposed by towed or attached implements or by difficult terrain. The frame must be built to endure, without failure or fatigue, a working life that may extend to more than forty years.

The Kirovets frame is a solidly made all-enclosed box section steel weldment. Frame parts are cut and folded, assembled, carefully welded and precision machined. A massive centre pivot articulates the front and rear parts of the frame through a trunnion yoke with large, fully sealed bearing surfaces. This yoke provides for relative movement of the front and rear frame elements with two degrees of freedom; +/-32o on the vertical axis and +/-16o on the longitudinal axis. It is this design feature that gives articulated tractors their advantageous characteristics; the ability to maintain all-wheel ground contact on undulating terrain, a compact turn radius and a steering geometry that, unlike fixed-frame front wheel steered machines, ensures that the leading and trailing wheels follow the same path.

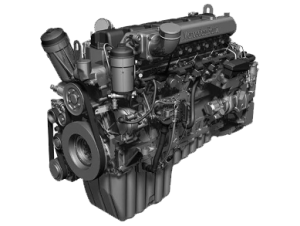

ENGINE

The power unit used in the Kirovets K-7M is the Mercedes Benz OM 460 LA, a 12.82 litre in-line six cylinder turbo-diesel with electronic engine management for superior fuel economy and emissions performance. The engine is configured to Euro IIIA standard and does not require the use of Adblue® or a DPF. The engine has a noise optimised cast iron block with wet cylinder liners and separate four-valve cylinder heads, oil-cooled aluminium pistons, precision forged connecting rods and an induction-hardened seven-bearing crankshaft. The oil cooler is integrated within the crankcase. The Mercedes Benz engine offers exceptional quality, durability and fuel economy (205 g/kWh), thoroughly proven throughout the world in numerous agricultural and transportation equipment applications.

WHY CHOOSE KIROVETS?

Less to buy and less to run.

Listed price well below that of any equivalent tractor,

More cash in a farmer’s pocket.

TRANSMISSION

The Kirovets K-7 transmission combines the simplicity and robustness of a parallel shaft constant mesh mechanical transmission design with pneumatically controlled actuation for ease of operation. Sixteen forward and eight reverse speeds are available in four and two operating modes respectively. Within each selected mode, speeds can be shifted under power, without interruption, by hydraulically actuating the appropriate clutch pack. The clutch packs use multi-disc assemblies with alternating steel and ceramic plates. Modes are engaged by axially sliding sleeve gears on the middle and bottom shafts. Gears, forward and reverse, are selected by a joystick control. Modes and 2WD or 4WD are selected by switches and engaged by pneumatic actuators. An electronic control module protects the transmission from operator error. The transmission is pressure lubricated and has a front mounted oil cooler. The Kirovets design is thoroughly proven, reliable and durable. Spur gears are used throughout for power transmission efficiency and the elimination of axial thrust loads within the transmission casing. Gear wheels are processed from in-house cast and forged blanks on CNC gear-cutting machines. After heat treatment, tooth profiles are finish ground to precise final dimensions and geometry (DIN class 7 & 8). Transmissions are hand assembled by skilled technicians and thoroughly bench tested prior to installation on the tractor frame.

AXLES

Power is transmitted via cardan shafts to the front and rear axles. The front axle is suspended on truck-type leaf springs for improved ride comfort. The Kirovets axle design is of a unique “no-spin” design that automatically lock in the straight ahead position to provide exceptional tractive performance. An important feature is that the rear axle is disengaged for smooth running in transport mode and on hard surfaces. Planetary gear assemblies are mounted, together with the truck-type air brakes, on the axle extremities. The axle design mounts wheels with wide, deep-section 710/70R38 low compaction tyres. The tyres have an R1W tread pattern to enhance ride comfort. Dual wheels and spacers are available as an option. The design of the transmission, axles and wheel set, taken together, provide Kirovets tractors with exceptional tractive efficiency

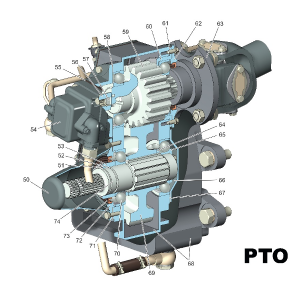

ATTACHMENTS

Equipment for mounting all types of attached and trailed implements is fitted to a Kirovets as standard. Towed implements are attached by a floating drawbar and attached implements by an ISO cat. IV 3-point linkage with Walterscheid lower links. Hydraulics are load sensing type with four pairs of outputs plus returns. The system is supplied by a Bosch-Rexroth A10VNO85 axial flow pump with180 l/min capacity. A 1000 r/min PTO with 44.45 mm (1³/4″) 20 spline output shaft is included.

CAB

The Kirovets cab is a highly functional, solidly built ROPs/FOPs structure. The cab is mounted and lined with vibration and noise insulation materials and glazed with solar-resistant glass. The cab is pressurised. Air-conditioning, heating, radio and fire extinguisher are standard. The control column is adjustable for reach and height. A fully adjustable suspended seat and folding passenger seat are included.